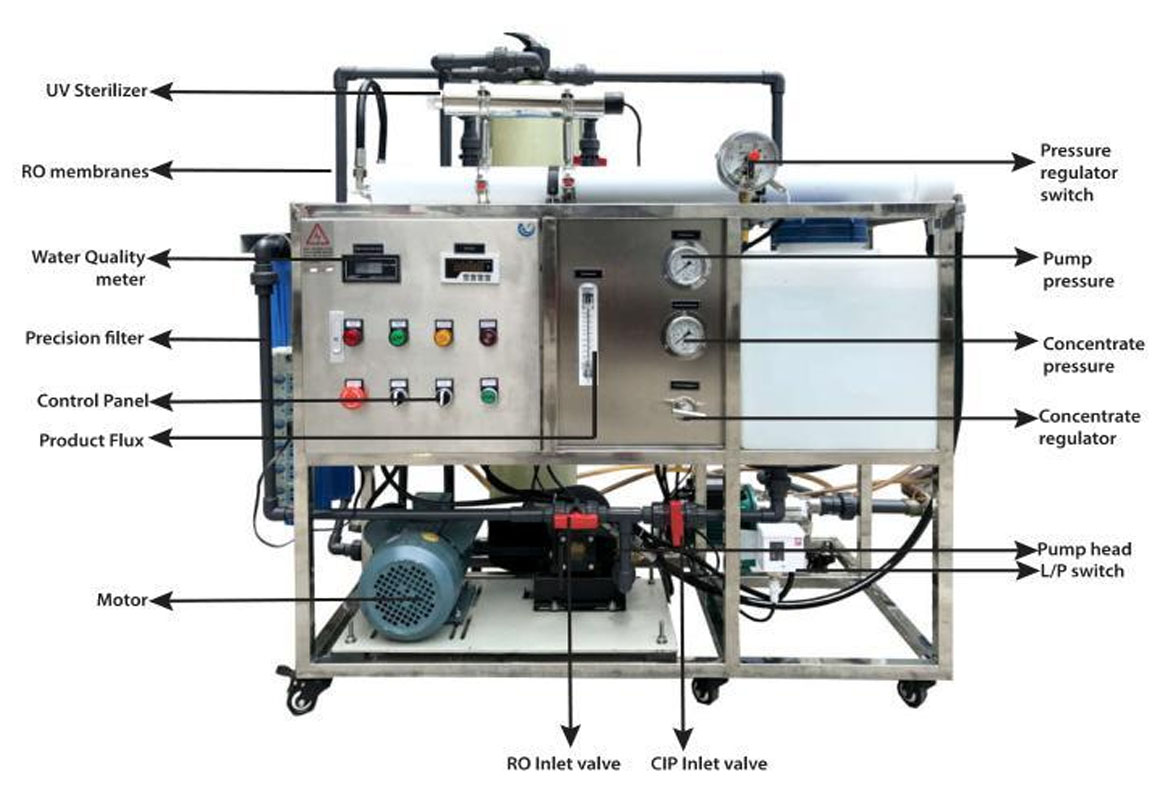

Portable & Mobile RO System

Portable water maker is designed for compact installation space on ocean ships small boats, yacht cabins, and humid environments. The frame is made of SS 316 round pipe with rubber feet. The unit is easy to hold and carry. The machine converts seawater to potable drinking water.

A reverse osmosis desalination system is justifiable anywhere there is a shortage fresh water and a good source of available brackish or seawater. While many desalination plants have been constructed in dry environments and island coastal communities. But as viable freshwater sources become more scarce, both industry and municipalities are adopting RO-based desalination.