Products

WHY CUSTOMERS LOVE US

Ultraviolet water Sterilizer-Vertical Type 12-24-36 GPM

Ultra Tec® Water Treatment Equipment LLC, a renowned diversified Water Treatment Company having decades' of excellent Products and Services experience in Water Treatment Industry. We feel immense pleasure in informing you that we have been successfully providing our best quality Products and Services to the distinguished organizations located all over the MENA (Middle East and North Africa).

Great for well water and/or as an add on to any whole house water filters or any other 12 GPM , 24 GPM, 36 GPM vertical flow filtration application. Ultraviolet Water Sterilizer System manufactured with axial flow reactors in 304 stainless steel and comes with 2” MNPT connections. The hard glass germicidal lamps provide an economical way of treating water requiring a 99.99% reduction of bacteria and virus and protozoa. This process is accomplished without adding any harmful chemicals to your drinking water. Ultraviolet Water Sterilizer System is the most ecological way of treating your water… and all for just pennies a day!

SEE CASE STUDIES

WHY CUSTOMERS LOVE US

Whole House Ultraviolet Sterilizer Filter System

water sterilizers are designed specifically to kill harmful microorganisms such as bacteria and viruses in untreated water supplies (well water or surface water systems). Ultraviolet (UV) systems are commonly installed by homeowners who have received a positive coli-form.

- 9 Gallons Per Minute

- 99.99% Destruction of Bacteria, Cysts & Virus

- Easy Installation

- 3/4″ – 1″ Combo Port

WHY CUSTOMERS LOVE US

48 GPM Ultraviolet Water Sterilizer System with Alarm

Great for well water and/or as an add on to any whole house, commercial and industrial water filters or any other 48 GPM flow filtration application. 48 GPM Ultraviolet Water Sterilizer System manufactured with axial flow reactors in 304 stainless steel and comes with 1.5” MNPT connections. The hard glass germicidal lamps provide an economical way of treating water requiring a 99.99% reduction of bacteria and virus and protozoa. This process is without adding any harmful chemicals to your drinking water. Ultraviolet Water Sterilizer System is the most ecological way of treating your water and all for just pennies a day!

Categories: Ultraviolet UV Sterilizer, UltraViolet UV Sterilizers

WHY CUSTOMERS LOVE US

Gray Water STP Sewage Treatment Plant for Marine Ships

Grey and Black Water Treatment System Marine Sewage Treatment Plant for Ship (STP)

- Type: Marine Sewage Treatment Plant

- Method: Physical Treatment

- Usage: Marine

- Rated Capacity(P): 10-400 Men Grey and Black Water Treatment System

- Electricity: AC 380V, 50 Hz, 3 Phase / AC 440V, 60 Hz, 3 Phase

Categories: Ultrafiltration UF System, Ultrafiltration UF System

WHY CUSTOMERS LOVE US

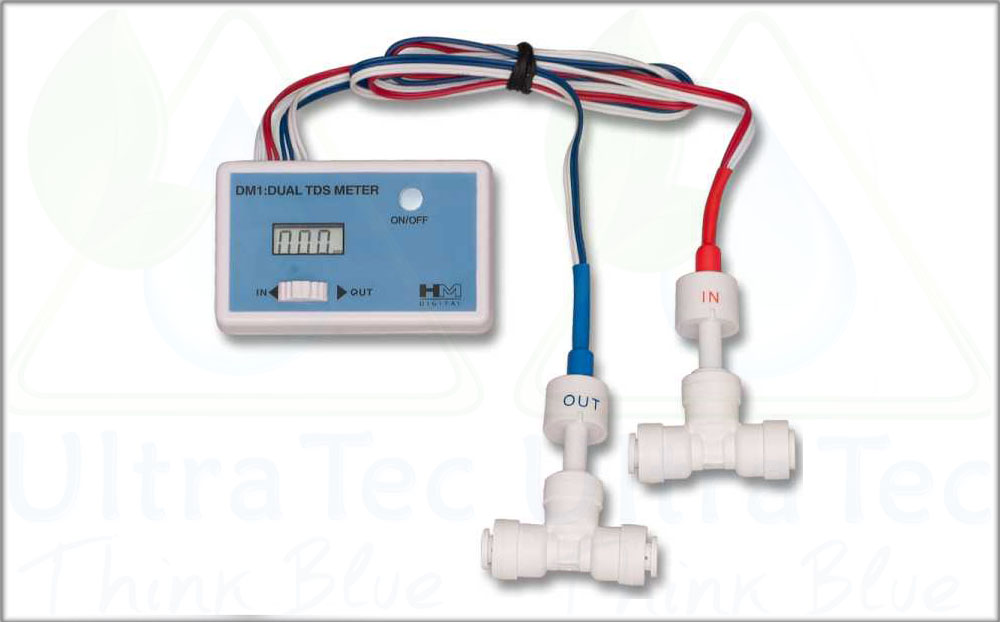

Inline Digital TDS Meter

Displays TDS levels of the Feed Water and Product Water with in & out electrode probes Factory calibrated and highly efficient and accurate (±2%) due to its advanced microprocessor technology Dual Range – Measures from 0 – 999ppm, with a resolution of 1ppm.

WHY CUSTOMERS LOVE US

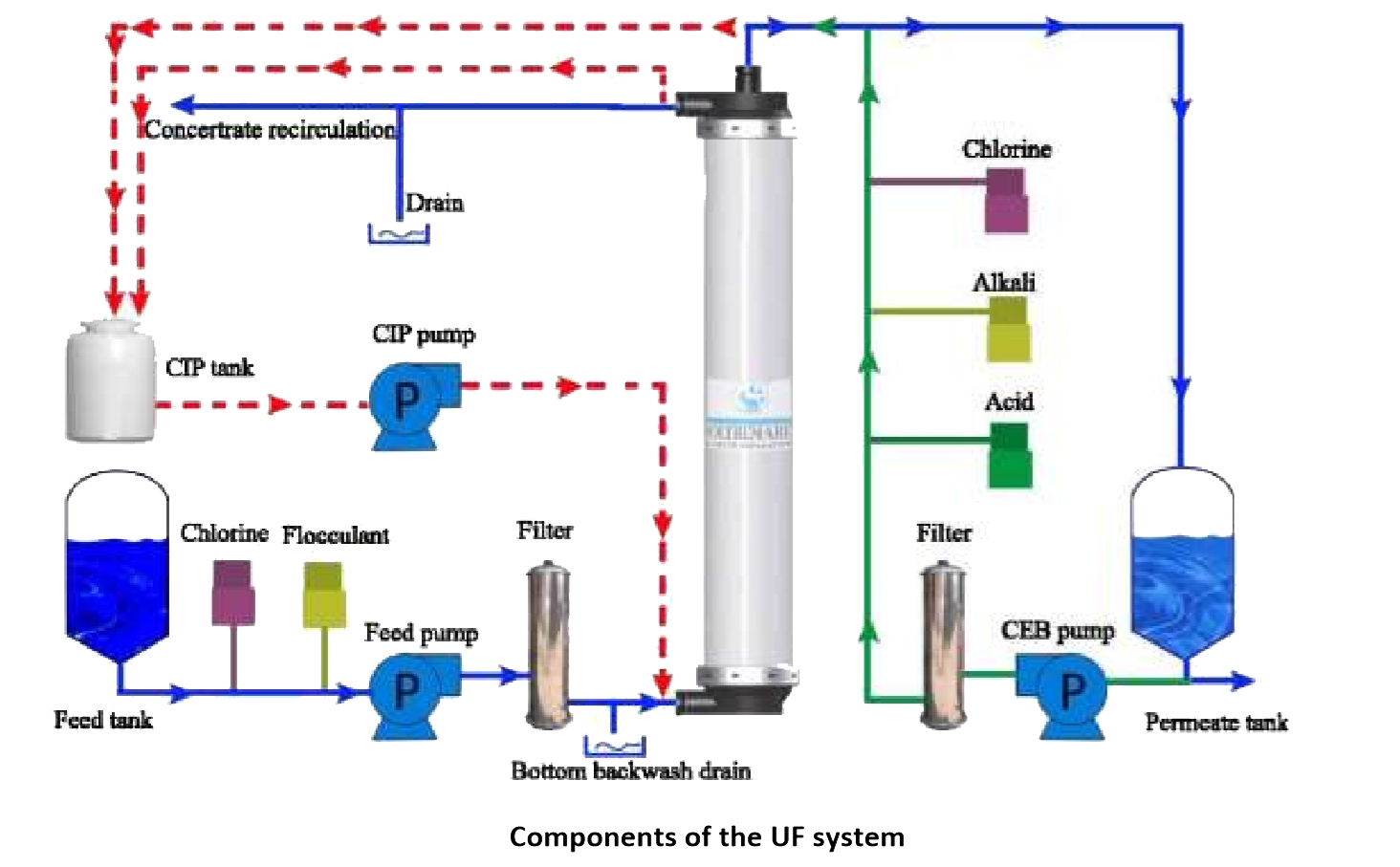

Ultrafiltration (UF) Plants Manufacturers, Suppliers for Wastewater System

Ultrafiltration (UF) is a crucial purification technology used for the production of high-purity water in the several industries. Strategically combined with other purification technologies in a complete water and Wastewater system. Ultra Tec Engineers UF Plants are designed for a selection of industrial & industrial applications requiring top quality equipment with a quick delivery and competitive worth. These pre-engineered, pre-assembled and factory tested units minimize installation and begin-up time.

Operating Principle :

Ultra filtration is a distinctive pressure-driven physical separation process in that the water is knowledgeable porous (partially permeable) membranes with pore sizes within the range of 0.1 to 0.01 micron.

These membranes are in the form of long hollow fibers. The result’s high pure water free from physical and biological contamination. Ultra filtration isn’t basically completely different from microfiltration or nano filtration, except in terms of the dimensions of the molecules it retains. Ultra filtration is applied in cross-flow or dead-end mode and separation in ultra-filtration undergoes concentration polarization.

Salient Features :

- Low fouling Hydrophilic UF membrane

- Excellent filter performance with high flux

- High removal efficiency of bacteria and viruses

- Periodically back washed and air scoured for consistent performance

- Simple, vertical, modular design allows low cost, compact systems

- Fully automated control system for backwashing process

- Advanced custom designed Control Cubicle

- Stainless / carbon steel equipment frame

- Permeate, back pulse pumps, membrane aeration blowers and associated valving mounted on equipment frame

- Control panel with standard PLC and HMI interface mounted on equipment frame.

- Permeate, back pulse pumps, membrane aeration blowers and associated valving mounted on equipment frame

- High end electrical actuated operating valves.

- All alarm and shut down conditions are indicated on the control interface.

Advantages :

- User-friendly programmable controlse

- High quality components ensure continuous, reliable operation

- Pre-engineered & factory tested systems mean easy installation

- CEB (Chemical enhance backwash) connections maximize system availability

- Produces high quality Water.

- Easily integrated into an existing facility

- Requires minimal operator supervision

- Most comprehensive cleaning capability ensures peak system performance

- Ideal for direct reuse

Available Options:

- Chemically Enhanced Backwash (CEB)

- Feed/backwash oxidizer (dosing system)

- Membrane cleaning skid (CIP)

- 380-415V/3Ph/50Hz power supply

- Online turbidity monitor

- Stainless steel multi-stage feed pump

- Feed pump VFD

- PLC + HMI

- Filtrate (backwash) tank (HDPE)

- Pressure Transducers

- Blower (for backwash)

- Duplex 2205 screen (versus SS 316)

WHY CUSTOMERS LOVE US

Industrial Ultra Filtration Systems

Ultra Filtration is a pressure driven membrane separation process that removes suspended or particulate matter (including colloids & silt) from water. Ultra Filtration is more reliable than conventional multimedia Filtration that removes approx. 10 micron or larger matter where a UF membrane pore size ranges from 0.01 to 0.10 micron. Ultra Filtration also efficiently removes bacteria and most viruses.

Standard Features:

- UF modules (PVC)

- Stainless steel backwash pump

- 150 um flushable screen

- Schedule 80 PVC piping

- 460V/3Ph/60Hz power supply

- Microprocessor control panel

- Motor starters

- NEMA 12 enclosure

- Differential pressure switch

- Liquid filled pressure gauges (panel mount)

- Electrically actuated valves

- Flow meter

Systems Applications:

- RO pretreatment

- Drinking water treatment

- Tertiary wastewater or grey water treatment

- Process separation or recovery

Ultra Filtration System Works:

The figure below is a typical process flow diagram for a UF system. Ultra filtration systems eliminate the need for clarifiers and multimedia filters. Standard design is based on a UF module with outside-in flow configuration which allows for less plugging, higher solids loading, higher flow area and easy cleaning. The primary flow design is dead-end filtration.

WHY CUSTOMERS LOVE US

Seawater RO Watermakers for marine ships & oil rigs

With water maker, you have the power to manually optimize and configure your system settings according to any water condition you encounter. Pressure and temperature are balanced using a pressure regulating knob, allowing boaters to operate the Water Maker in any ocean condition. Operations are easily optimized in seconds simply by turning the knob to your preferred setting. The quiet high pressure pump runs smooth and is also customizable. Capable of producing between 450 – 1,800 GPD (1,703 – 6,814 LPD).

Category: Water Makers

Technology:

- Digital Menu with full color LCD touch screen

- Manage critical functions from any location. Maintain, guide, and configure the Water Maker anyway you wish using the user friendly touch screen display or the optional touch screen remote.

- Simple-to-use touch screen displays pictorial images of all operating conditions.

- Digital and bar graph readout of all system conditions in U.S. Standard or Metric.

- Computer interface ready

Materials:

- Dedicated heavy duty Magnetic Latching Relays for each motor integrated in the system.

- 316 Stainless Steel Pressure Transducers for accurate measurement of system functions.

- New High rejection / high yield membrane element that produces higher quality product water in a smaller space.

- Fiberglass Reinforced High Pressure Membrane Vessel is stronger and eliminates corrosion.

WHY CUSTOMERS LOVE US

Copper silver ionization mineral pure

All newly designed models feature state-of-the-art circuitry design using the latest in digital technology. Clearly the most accurate and reliable mineral ionization system in the world. Unit will dynamically adjust output voltage to match electrode conditions extending the life of the control unit and savings as much as 60% in electricity usage.

Clear window for easy monitoring and secure latch.

- Unit have control box (work on 110/220 VAC automatically)

- 6 electrodes (75,000 gallons water treated 1 per set )

- unique clear flow cell chamber, electrode wire, mounting brackets and test kit

- All models NSF Standard 50 approved. NASA licensed technology.

- Computer interface ready

All newly designed models feature state-of-the-art circuitry design using the latest in digital technology. Clearly the most accurate and reliable mineral ionization system in the world.

WHY CUSTOMERS LOVE US

Automatic Self Cleaning Water Filter

Self cleaning filters to remove contamination and oversize materials from your liquid products. Ultra Tec® self cleaning filters with wide range of models covering a variety of flow rates and filtration degree, together with low consumptions water, make it the most effective system. With a wide range of self cleaning industrial filters to suit your unique processing requirements, you can be rest assured that your liquid products will be free from contamination.

Categories: Self Cleaning Filter, Self Cleaning Filter

Self-cleaning automatic filter KAF

The KAF which does not only use the back flush effect caused by the simple pressure drop to outside lower pressure than the working pressure the self cleaning back flush filter creates its own back flush effect in the gap between the cleaning disc and the strainer insert. The insert can be made out of wedged wire profiles or a perforated plate. In some special applications also stainless steel or alloy mesh is used. The wedged wire filter screen can be made out of stainless steel SS 316 or materials like super duplex or duplex SS. If perforated plate is used for filter degrees over or 1 mm than as well stainless steel and also duplex Ss’ or titanium perforated plates are used. This kind of self cleaning filters has following operating features.

Features & Benefits:

Increase your production rates With our unique self cleaning design. there are no stoppages to change filter elements, and no slowing of throughput as filter elements block. Improve your product quality. Our self cleaning filters are totally enclosed so no product contamination is possible. Reduce your costs – There are no continual costs of replacing filter media and no disposal costs. You will also see a reduction in wasted liquid product, labor costs and downtime. Safeguard the health and safety of your operators.

our industrial filters are totally enclosed, which means no fumes and limited operator exposure to liquid.

Containerized RO Plants Supplier in UAE

We are Supplier of all Kind Containerized RO Plants, Containerized Sea Water RO Plants in Dubai UAE, industrial water treatment plants, drinking water, brackish water treatment, well water filtration, irrigation water plants and home water purification systems

The solution is complete with all internal piping and wiring factory-built. The whole plant has been performance and pressure tested in our factory. The containers delivered with and without installation and equipped with lighting, air-conditioning, door-in-door, emergency shower, etc.

As a standard feature our SWRO plants are designed with the most updated and efficient energy recovery system “The Pressure Exchanger” PE which is a 60% energy reduction in comparison to a conventional SWRO plant using 7.0 to 8.0 kWh/m³ ~ 26 to 30 kWh/k-gallons.

Categories: industrial RO Plant, Sea water RO Plant

WHY CUSTOMERS LOVE US

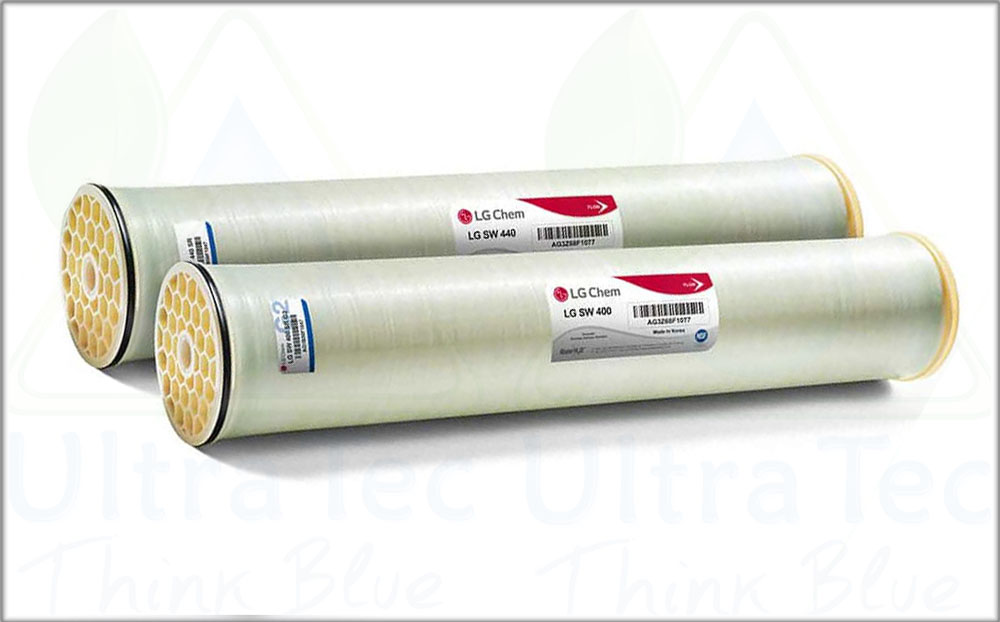

LG RO Membrane SW 400 R

LG Chem’s NanoH2O™ seawater RO membranes, incorporated with innovative Thin Film Nanocomposite (TFN) technology, reduce the cost of desalination while delivering superior water quality. Our seawater RO membranes provide industry leading salt rejection and produce 20% more flow than membranes manufactured with conventional technologies. We continue to leverage the technological advantages of our seawater RO membranes to expand our market share accruing more than 1,000 Million Liter per Day (MLD)

Description

LG Seawater RO Membrane – LG SW 400 R

The Reverse Osmosis water filtration technology Membrane by LG is designed for Seawater / High Salinity Water applications that require a psi of 800. This Membrane uses Reverse Osmosis water filtration technology to take out 99.85% of contaminants found in the feedwater, which makes it best suited for medium to high salinity seawater applications.

The Reverse Osmosis water filtration technology Membrane LG SW-400-R is made in the Republic of Korea. The advantages in using the LG SW-400-R Membrane are offer a combination of high rejection and low energy requirements to reduce the total cost of desalination. LG is a United States company well known for high-quality Membrane manufacturing for effective Reverse Osmosis water filtration technology.

Product Details:

- SKU/Part Number: LG SW-400-R/li>

- Brand/Manufacturer: LG

- Country of Manufacture: Republic of Korea

- Material/Type: N/A

- Technology: Reverse Osmosis water filtration technology

- Water Type: Best suited for Seawater / High Salinity Water applications

- Application(s): Medium to high salinity seawater applications

- Advantage(s): Offer a combination of high rejection and low energy requirements to reduce the total cost of desalination